I’ve been working on installing a watering system in my garden. Even though it seems simple on the surface, it took me a while to work out how to do things.

Part 1 – The Solenoid Valves and Manifold

First of all I sketeched out the garden beds I wanted to install the irrigation system into, and then I planned how many runs of dripper line I wanted. For the garden beds in question I needed two lines and three lines respectively.

The garden beds are on the side of our house with the closest water source being under the kitchen sink. I decided to install the solenoid valves and manifold under the kitchen sink. I put together my bill of materials and bought from Wet Earth who have been very helpful in advising me.

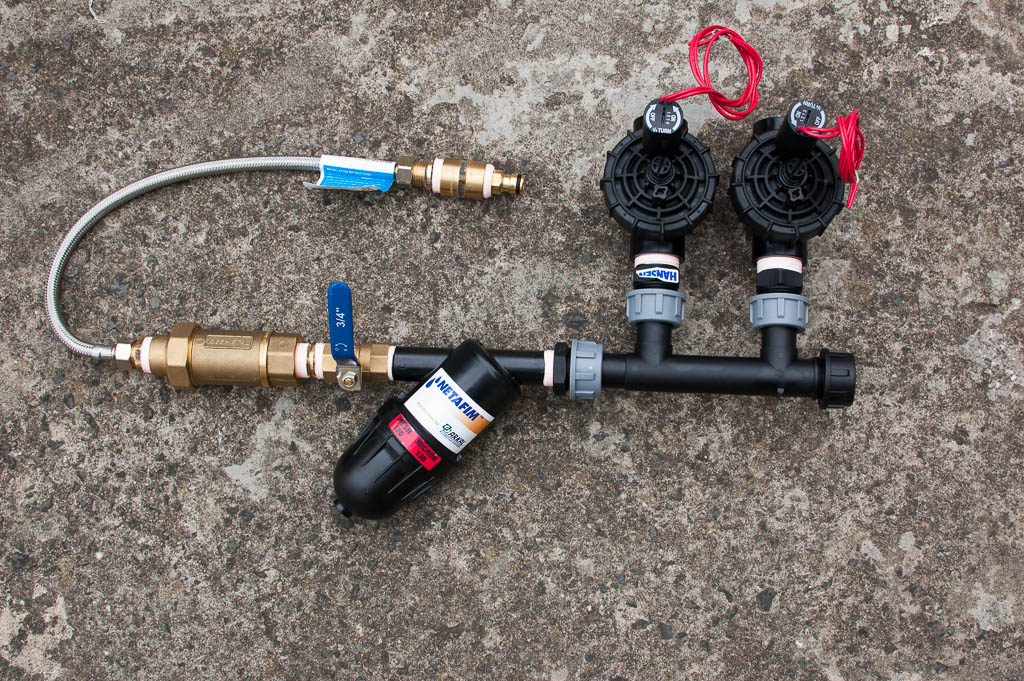

I measured the space available under the sink and put the pieces together to ensure they would fit. My first mistake was not testing the whole rig before installing. I found that it leaked and I spent a hours fiddling around under the sink trying to fix it. It was very difficult working under the sink and in the end pulled the whole lot out so I could test it all for leaks on the bench. I made a little test harness which you can see in the center of the photo below. It allowed me to connect the hose to the system and leave it pressurised to look for leaks.

Starting from the top middle and following around anti-clockwise are:

- Hose adaptor for testing purposes

- Flexi hose.

- Back flow prevention valve

- Ball valve so I can turn the whole thing off if I need to.

- Filter

- Manifold

- 2 x Hunter Jar Top solenoide Valves

Under my sink there was already an unused tee in the cold water line. I’ll connect the flexi hose to that. I have heard that these flexi lines don’t last for ever and they need to be changed every 5-10 years or so.

The biggest problem I had was that all my threaded connections leaked. I was using plumber’s pink thread tape (the thicker stuff) but they still leaked. I asked at the pluming shop and was told that I should wind the thick tape twice around the thread before screwing them together, which I duly did, but it still leaked. I went back to the plumbing shop and asked more advice and was told that I should be wrapping the thread in 6-10 turns of the thick tape. Once I did that the seals were good. The guy at the irrigation shop told me to use 9 turns of thick tape, or 18 turns of thin on the black nylon glass re-inforced threaded fittings. This seems to be working well too.

After testing on the bench I finally managed to seal all the threaded connections only to find the valve heads were leaking, slow leaks but definitely leaking. I called Wet Earth and they told me to pull the head off the valve and ensure the diaphragms were clean. I did this and repressurised the system on my test harness. After leaving it at full presssure for several hours, and very slow drips coming out of the valve heads, it eventually seemed dry up. I suspect there was water in the thread or between the diaphragm and the head of the collar of the valve that was slowly dripping out making me think it was leaking, but the water eventually dried up and thats why I think it was just water in the thread.

I was using spanners for working on the various bits but then I got some molegrips and I have found these to be much better for the job. Much quicker to get parts on and off. Also molegrips open up mich wider. My 10″ shifter wasn’t wide enough for the nyglass fittings.

Part 2 – Dripper Lines

I made the ends for the dripper lines on the bench. For each bed I needed a head which would consist of 2 elbows, a tee for the water inlet and a vacuum break, and a tail consisting of 2 elbows, and a automatic flush valve. I measured up the 13mm poly tubing and put it together. I started out using hot water to warm the pipe to make it easier to insert the barbed fittings but then I had the idea of using the heat gun. The heat gun is much easer. I also found that the 13mm poly tubing was quite easy to straighten by using the heat gun to warm a section of pipe, and then holding it straight while it cools. It makes things slightly easier to work with, not having the pipe bending all over the place. It is easy to overheat the poly pipe with the heat gun though so you do have to be careful with it.

I laid the dripper line in the beds and hooked up the head and tail ends I made earlier. Incidentally I found the mole grips were also very good here for squeezing closed the poly pipe clips.

Above you can see three dripper lines (the middle one is a bit obscured) and the round automatic flush valve. The pipes are held in place with retaining pins. They are useful for holding things in place as you lay the pipes and connect things up. I spaced the lines 25cm appart in this bed. The drippers are spaced at 30cms in the dripper line.

Above you can see the vacuum break valve and the way I ran the 13mm poly pipe to the dripper lines. In hindsight I could have probably made that quite a bit neater if I had used a 4 way cross splitter.

Leave a Reply